Metal Cutting Challenges and Metal Laser Cutting Machine

Aluminium laser cutting is very important for cutting complex shapes while maintaining best standard. Many producers do not do such jobs because of the hard level. Providing best standard needs know-how and experience to overcome the challenges offered aluminium laser cutting.

Aluminum cutting challenges

Aluminium cutting may not forever be the easiest of tasks. Due to the materials reflective nature, a laser beam can bounce back off it and destroy the laser cutter. Stainless steel is notorious for similar factors but aluminium surpasses the AISI grade in cutting difficulty.

Often times when talking these matters, coating the stuff with a non-reflective substance comes up. Definitely, it does not alleviate the risk. As soon as the coating is pierced and the aluminium begins melting, the highly reflective surface is exposed.

Those issues arise more often with aluminium grades that have less alloying elements, for instance AW 1050. The elements decrease the reflective effect of aluminium alloys.

Aluminium also tends to leave a burr. Depending on the producer, those burrs are either removed mechanically or rejected altogether with a right machine set up. Avoiding is, definitely, preferable as any extra working costs the client.

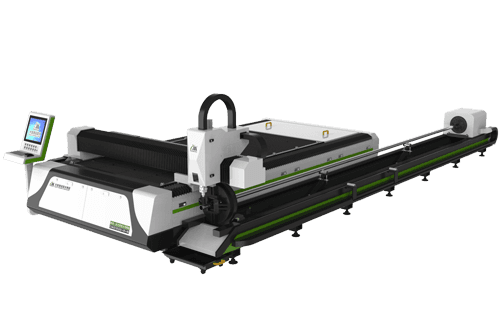

Picking the perfect laser cutting machine

Firstly, laser cutting is actually the way to go when cutting aluminium. Its high speed gather with the best expertise makes a burr-free cutting process possible. It is still vital to consider the aluminium grade. Higher grades with more alloying elements are simple to cut.

Another thing to bear in mind – does the producer have a CO2 laser or fiber laser? Fibre lasers are better suited to cut reflective stuff because of their build. CO2 lasers have a series of mirror within. The build is more susceptible by damage to the bouncing laser beam.

More power leads to excellent outcomes. Just in case you are still considering CO2 lasers for aluminium cutting, bear in mind that their power output is significantly little with similar parameters. We advise to pick a strong fiber laser. It make sure a best result, if used rightly.

Fighting aluminium reflection is doable via the use of right targeting distances. Keeping the target point on the farther end of the material also helps to decrease the occurrence of dross.

Laser cutting aluminium is the best choice until thickness up to 6.8 mm. from there, the standard suffers noticeably and the material needs extra machining. We would not suggest laser cutting past 20 mm.

When going past eight mm, water jet is the perfect cutting technology. Combining speed, standard a cheaper hourly rate makes water jetting the excellent choice for thick aluminium plates.

article source: https://www.hansymlaser.com/news/aluminium-cutting-challenges-and-aluminum-laser-cutting-machine

Media Contact

Company Name: Han’s Yueming Laser Group Co.,Ltd.

Contact Person: Media Relations

Email: Send Email

Phone: +86-769-22705851

Country: China

Website: https://www.hansymlaser.com/